LED strip lights have become incredibly popular for modern lighting designs, offering flexibility, efficiency, and a sleek aesthetic. When choosing the right type of LED strip for your project, you’ll likely encounter two major types: COB (Chip on Board) LED strips and SMD (Surface-Mounted Diode) LED strips. While both are effective, they have distinct differences that make them more suited for different applications.

In this blog, we’ll compare COB and SMD LED strips to help you understand their unique characteristics, strengths, and weaknesses, so you can make an informed choice for your lighting needs.

What is a COB LED Strip?

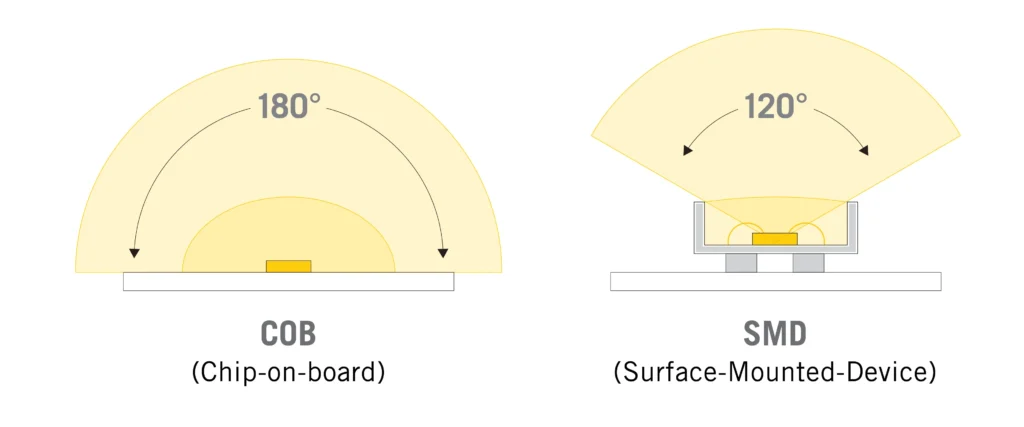

COB LED strips feature multiple LED chips packed closely together on a single circuit board. These chips are directly bonded to the surface of the strip, which creates a continuous line of light. Unlike traditional SMD LED strips, which have visible individual LED diodes, COB LED strips produce a smooth and uniform illumination, ideal for areas where seamless lighting is required.

Key Characteristics of COB LED Strips:

- Uniform Light Output: Due to the close proximity of the chips, COB strips emit a continuous, linear light with no visible dots.

- Higher Lumen Output: COB technology allows for more chips per meter, which results in brighter light.

- Heat Dissipation: The compact design of COB chips helps with better heat dissipation, ensuring a longer lifespan for the strip.

- Flexibility: COB strips are generally more flexible and can bend more easily around corners or curved surfaces.

What is an SMD LED Strip?

SMD LED strips are made using discrete diodes mounted onto a flexible PCB (Printed Circuit Board). These diodes are individually positioned, and each SMD LED can be single-color or multi-color (RGB, RGBW). SMD strips are more common and have been widely used for many years across various lighting applications.

Key Characteristics of SMD LED Strips:

- Visible Light Dots: Unlike COB strips, SMD strips have distinct LED dots that are noticeable when the strip is illuminated, depending on the density.

- Versatile Color Options: SMD strips are available in a wide range of options, including RGB, RGBW, tunable white, and more.

- Affordable: Due to their simpler construction, SMD strips are often more affordable than COB strips.

- Brightness Control: SMD LED strips come in various brightness levels (lumen output per meter), making them suitable for a range of applications.

COB vs. SMD: Key Differences

1. Light Quality

COB LED Strips: One of the standout features of COB strips is their continuous and uniform light output. The seamless, dot-free light is perfect for applications where a clean, uninterrupted light source is needed, such as under-cabinet lighting, retail displays, and architectural designs.

SMD LED Strips: SMD strips, on the other hand, have individual LEDs visible when lit. This can cause a “dotted” lighting effect, which is fine for decorative purposes but may not provide the smooth finish needed for accent or task lighting.

2. Brightness

COB LED Strips: COB strips tend to be brighter than SMD strips because more LED chips are packed onto a smaller surface area. This allows for higher lumen output per meter, making them ideal for areas where intense illumination is required.

SMD LED Strips: SMD strips can vary in brightness based on the type of LED diode used. For example, SMD 5050 LEDs are larger and brighter than SMD 2835 or SMD 3528. However, even the brightest SMD strips may not match the lumen output of COB strips in the same length.

3. Heat Dissipation

COB LED Strips: COB strips have better heat management due to their design, which means they tend to last longer without suffering from heat-related issues. The dense arrangement of the chips allows heat to dissipate more effectively.

SMD LED Strips: While SMD strips are generally reliable, their larger gaps between the diodes can lead to less efficient heat dissipation, potentially reducing their lifespan if not properly managed, especially in high-output configurations.

4. Color Options

COB LED Strips: COB technology is generally focused on single-color strips, such as warm white, cool white, or daylight. While tunable white, RGB and RGBW options exist, they are less common and more expensive than SMD strips.

SMD LED Strips: SMD strips are extremely versatile when it comes to color options. They are available in single-color options, but more importantly, they can be found in tunable white, RGB, RGBW, and addressable RGB/RGBW configurations, making them the better choice for colorful and dynamic lighting projects.

5. Application

COB LED Strips: Best for task lighting, display lighting, and areas where smooth, consistent light is crucial. Their dot-free appearance makes them ideal for premium installations and places where aesthetics are important, such as retail environments, art displays, or interior design features.

SMD LED Strips: Suitable for a wide range of applications, including decorative lighting, ambient lighting, and general-purpose illumination. They work well in home lighting, under-cabinet lights, and areas where you don’t mind seeing the individual LEDs.

6. Cost

COB LED Strips: Generally more expensive than SMD strips due to the higher density of LED chips and the more complex manufacturing process. However, the investment pays off in terms of performance, durability, and light quality.

SMD LED Strips: More cost-effective and widely available in various price ranges. This makes them an attractive option for DIYers or for large-scale projects where budget is a concern.

COB LED Strip: Best For…

- Task lighting

- Seamless and dot-free illumination

- Projects where brightness and light uniformity are essential

- High-end or commercial installations

SMD LED Strip: Best For…

- Decorative lighting

- Projects requiring color control (RGB, RGBW)

- Budget-conscious lighting solutions

- General-purpose or ambient lighting

Conclusion

Both COB and SMD LED strips offer unique benefits, but your choice depends on the specific needs of your project. COB LED strips are perfect for applications that require a high-quality, uniform light source with no visible dots, making them ideal for professional and high-end installations. On the other hand, SMD LED strips are more versatile, affordable, and suitable for projects where color control and cost-efficiency are priorities.

When planning your lighting design, take into account factors like brightness, color requirements, cost, and the overall aesthetic you’re aiming for. By understanding the differences between COB and SMD LED strips, you’ll be able to choose the perfect solution to meet your lighting needs!